March 18, 2025

Metal Masters: RH Simpson Sparks Opportunity for Women Welders

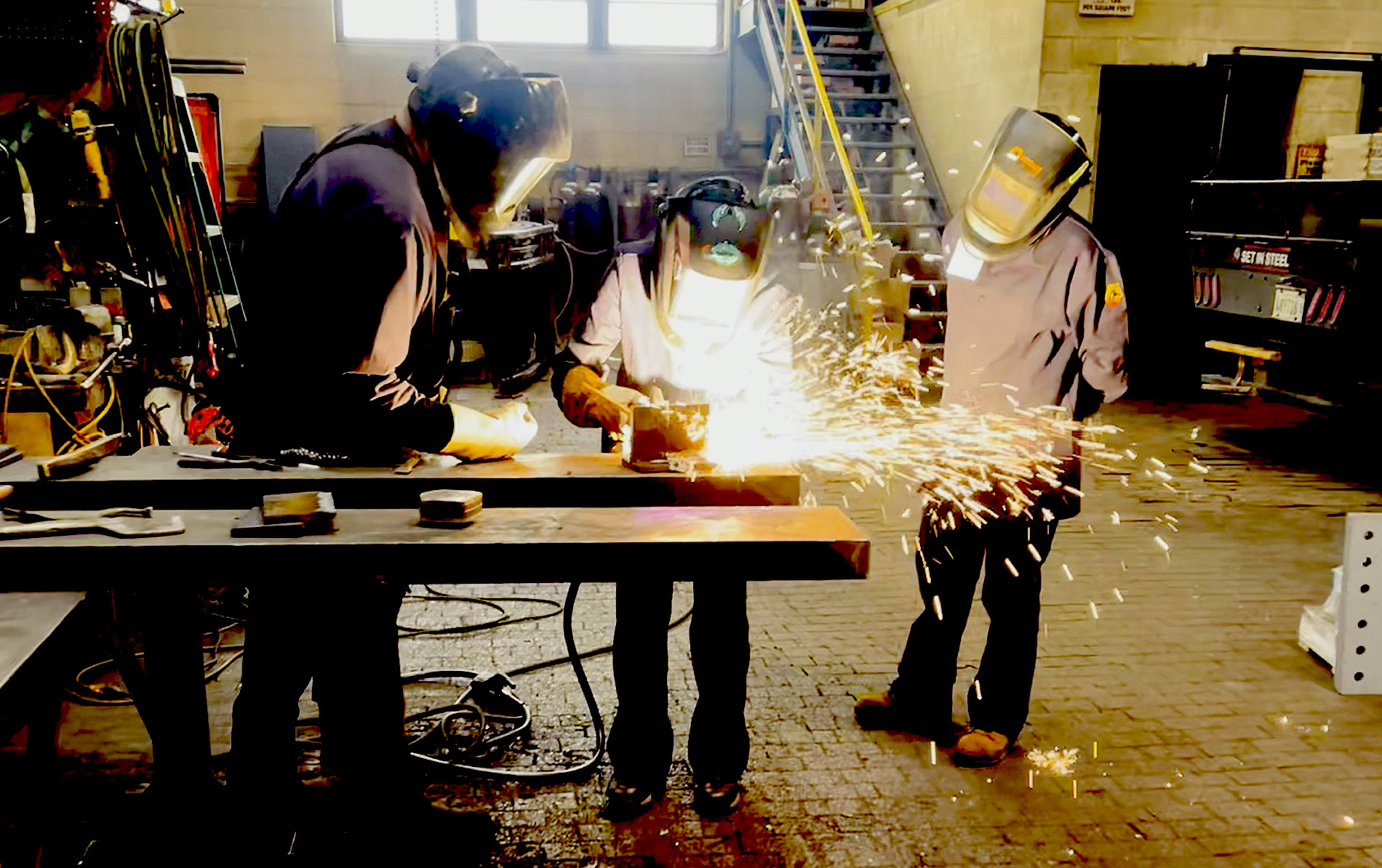

Fabricator opens shop doors to CWIT students, creating “weld-rounded” tradespeople

RH Simpson, a century-old ornamental and miscellaneous metals fabricator in Elmhurst, Illinois, has been working with Chicago Women in Trades (CWIT) to provide hands-on welding experience for students in the Women in Welding program. The partnership showcases how industry veterans can help create new opportunities in the construction trades. Kristopher Haas, the president of RH Simpson, talks about the collaboration with CWIT.

Q: How did RH Simpson come to partner with Chicago Women in Trades (CWIT)?

“We connected to CWIT through Power Construction, a company we’ve worked with for over 40 years. About two years ago, they introduced me to Renee Jones at CWIT. After my initial visit, we arranged a tour of our fabrication shop in Elmhurst with one of their welding classes. Since then, we’ve hosted the class seven times.

“We decided to get involved because we’ve been part of Chicago’s construction industry for over 100 years, and I saw CWIT as an organization we could meaningfully support. I’ve been in this industry since I was 16, and I’m passionate about seeing positive change. Personally, as a husband to an amazing wife who loves carpentry, a father to three daughters, and a brother to three awesome sisters, I want to support organizations that empower women to build careers and pursue their dreams—no matter the industry.”

Q: What inspired the field trips and hands-on training for the Women in Welding program?

“This is a very valuable part of the CWIT training program. Welding spans many industries, and even in construction, we have both fabrication and installation sides with different techniques and work environments. We provide an introduction to ornamental and miscellaneous metal fabrication.

“During visits, students are immersed in a working shop environment—it’s loud, with welding arcs flashing, grinding sparks flying, and materials being moved around them. About 60% of our team provides instruction while others continue normal operations. Students work on actual projects in production and develop skills beyond just welding. They experience what it’s really like to be part of a fabrication team, which is completely different from field installation work, where conditions are less controlled and equipment more portable.

“Students get to try everything: tig-welding delicate pieces, cutting metal with oxy-fuel torches, operating punching and shearing equipment, and finishing work through grinding and polishing—all skills our best fabricators need to master. This hands-on variety gives them a realistic picture of daily shop life beyond classroom training. And there’s always excitement when they try carbon-arc gouging!”

Carbon arc gouging

From left to right: Tonnickie Singleton (CWIT welding case manager), Kristopher Haas and Matt Prodehl (RH Simpson), and Desiree Guzman (CWIT welding program coordinator and instructor)

Q: What advice do you have for welding students who want to work in a fabrication shop like R.H. Simpson?

“One common question is about pay compared to field crews. Our shop workers (Local 853) earn less than field ironworkers (Local 63), but shop work offers better conditions, steady hours, and a consistent location.

“It’s important to develop a well-rounded skill set. Many students arrive thinking they’ll have their hood down welding all day, but that’s a misconception. In reality, even our best welders spend much of their time measuring, fitting, reading blueprints, preparing materials, and problem-solving. Be ready to learn skills beyond welding—we teach these through hands-on training, but an eagerness to expand your capabilities makes a huge difference.

“The work can involve repetition—like fabricating 160 similar railings for a high-rise, with the same welds over and over. But what keeps it exciting are projects like the Aviary Exhibit at Brookfield Zoo, which involved complex structural welding and creative problem-solving.

“We display completed project photos on our shop wall, which helps our team see the final impact of their work after it leaves our facility. Sometimes, the most rewarding part is simply the satisfaction of laying down a perfect weld bead and taking pride in your craftsmanship.”

Q: What stands out about CWIT’s Women in Welding program?

“The excitement and enthusiasm when classes arrive. Everyone always shows up with smiles and ready to get some hands-on training. These women are actively pursuing welding careers because they want to learn a trade. The skills they gain through CWIT are solid and applicable to our industry. Desiree and her team are doing a fantastic job preparing them. We even hired a CWIT graduate in 2024. The program also creates internal company impact. It’s awesome seeing our crew light up when teaching and providing hands-on training. Their pride and enthusiasm really shows.”

Q: What opportunities do you see for building our work together?

“I’d love to get some of our subcontracted installers to partner with us and provide hands-on fieldwork experience. That would give students the full picture of our metal work from shop to installation. We will also continue to emphasize the multiple skills that complement welding. A well-rounded tradesperson is key to a good shop.”